Our Supply Chain

We only work with suppliers and partners that share our values – for us it’s always about creating transparent, long-lasting relationships with people that we can trust. Plus, we measure the climate impact of our supply chain, too. Unless we know our full environmental impact, we’re unable to take action that will create long-lasting change.

Organic Cotton fresh after harvest in Turkey.

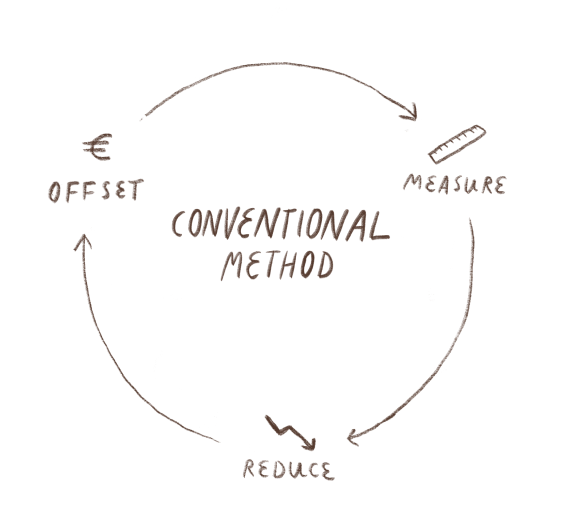

Why carbon emissions?

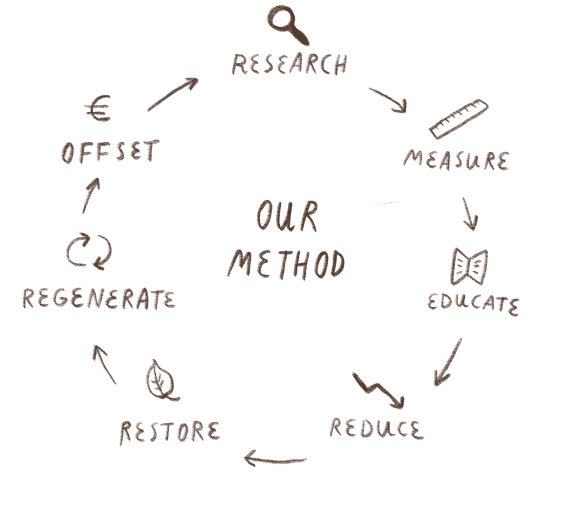

Climate change affects every part of our planet. We want to be changemakers, and take concrete actions towards stabilizing our climate. That’s why we work with carbon emissions as a KPI. The framework we use is inspired by the “measure, reduce, offset” framework. We added a few more to make it more holistic. For us, it looks something like this: “research, measure, educate, reduce, restore, regenerate and offset”.

We not only measure our carbon emissions across our entire value chain – we also transparently report it, and track our progress over time.

We set a target to reduce our carbon intensity by 50% by 2025 with 2020 as our baseline. But what does carbon intensity actually mean? We track our CO2 emissions relative to our revenue. As a young company that has ambitions to grow, we want to track our carbon emissions alongside our revenue growth to make sure carbon reductions are always in focus.

Büyük Menderes Basin in Turkey

Our CO2 emissions

We calculate our CO2 emissions following the Greenhouse Gas (GHG) Protocol. Businesses worldwide use this framework to understand, quantify and manage their GHG emissions.

Here’s how we use the framework: The GHG Protocol classifies emissions into three scopes. First, we collect all information on the fuel used by our company car as well as our water, heating and electricity consumption in our office and store. That’s what the GHG protocol calls Scope 1 and Scope 2 emissions. Then we calculate the emissions of our products – from raw material to garment assembly as well as the emissions from transport to our warehouses, waste generated in our office and store, business travel, packaging, storage, transport from our warehouses to consumers, and consumer use and end of life. That’s what the GHG protocol calls Scope 3 emissions.

Here’s what our climate impact looks like across our entire supply chain:

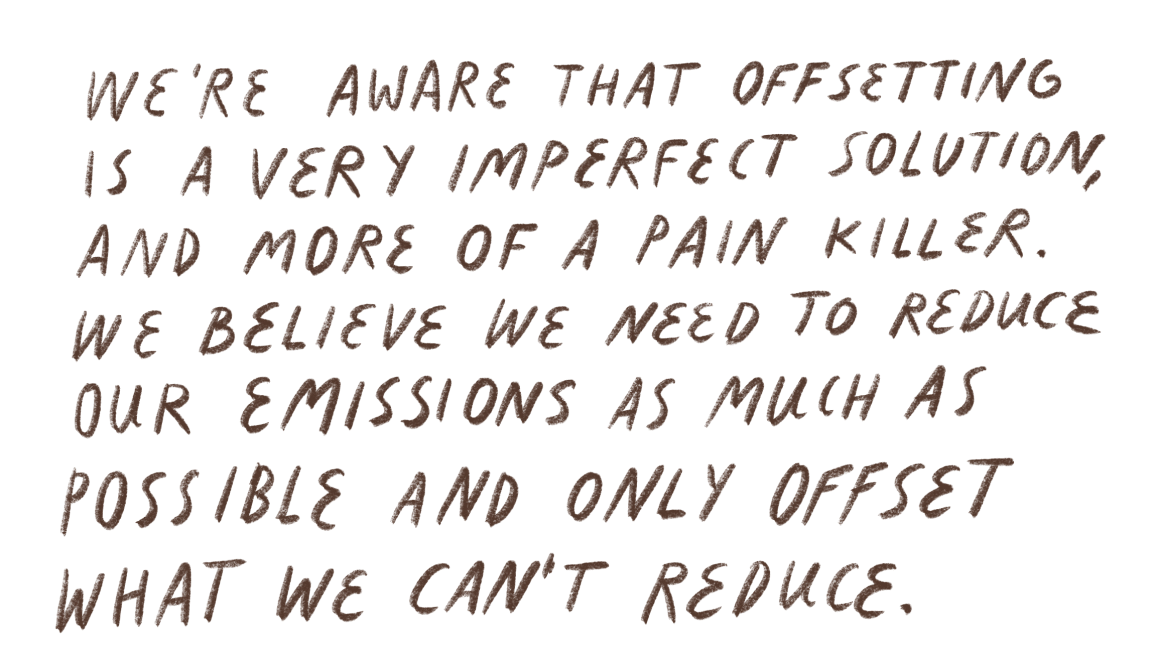

To ensure our data is valid, reliable and accurate, we collaborate with Berlin-based Vaayu, and UK-based One Carbon World. Vaayu supports us in calculating and validating our emissions in real time. One Carbon World also helps us to select projects to offset 100% of our carbon emissions through UN-vetted projects. We’re aware that offsetting is a very imperfect solution, and more of a pain killer. We believe we need to reduce our emissions as much as possible and only offset what we can’t reduce.

Carbon neutrality

By definition, carbon neutrality is the balance between emitting carbon and absorbing carbon emissions from carbon sinks. Carbon sinks are any systems that absorb more carbon than they emit, such as forests, soils and oceans. To us, being carbon neutral means that any CO2 released into the atmosphere from our company’s activities is balanced by an equivalent amount being removed. We do this together with our offsetting partner One Carbon World, and our membership with UNFCC’s Climate Neutral Now Initiative.

Transparency

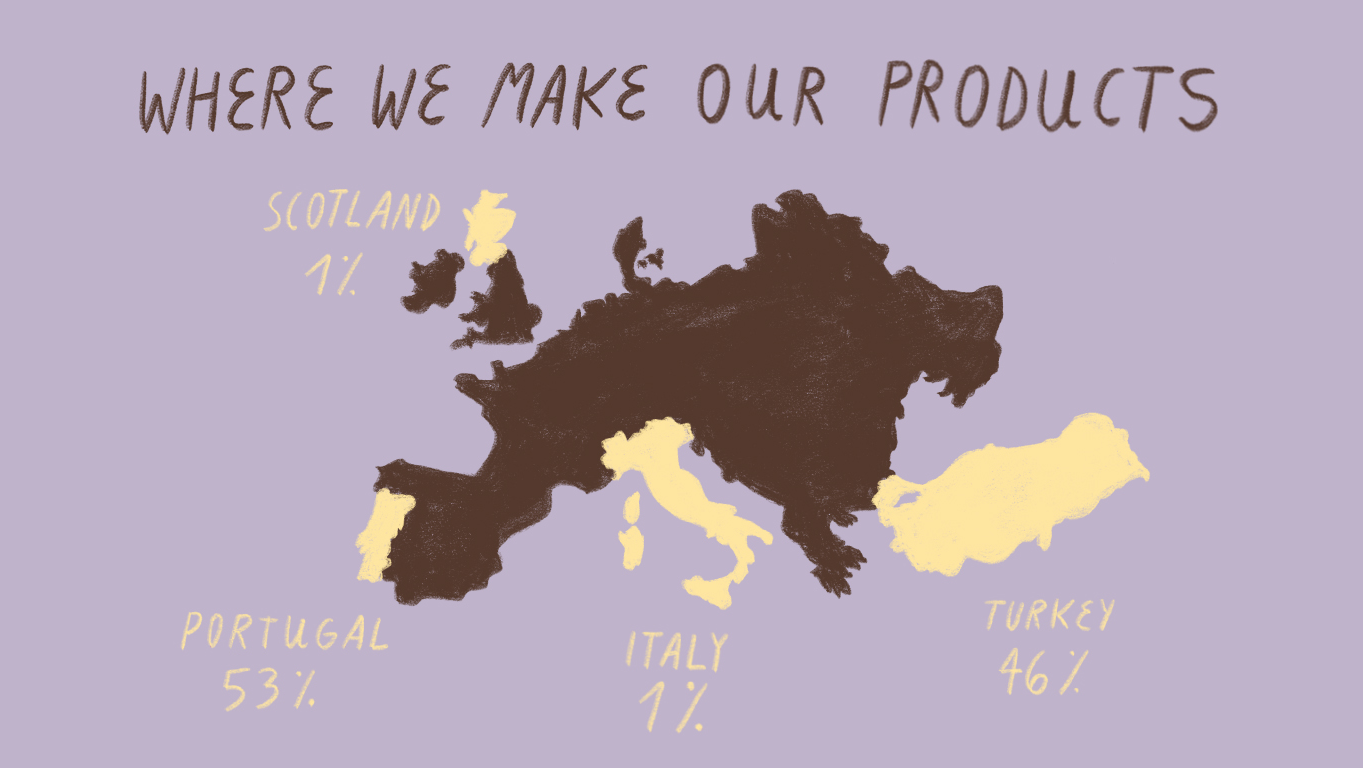

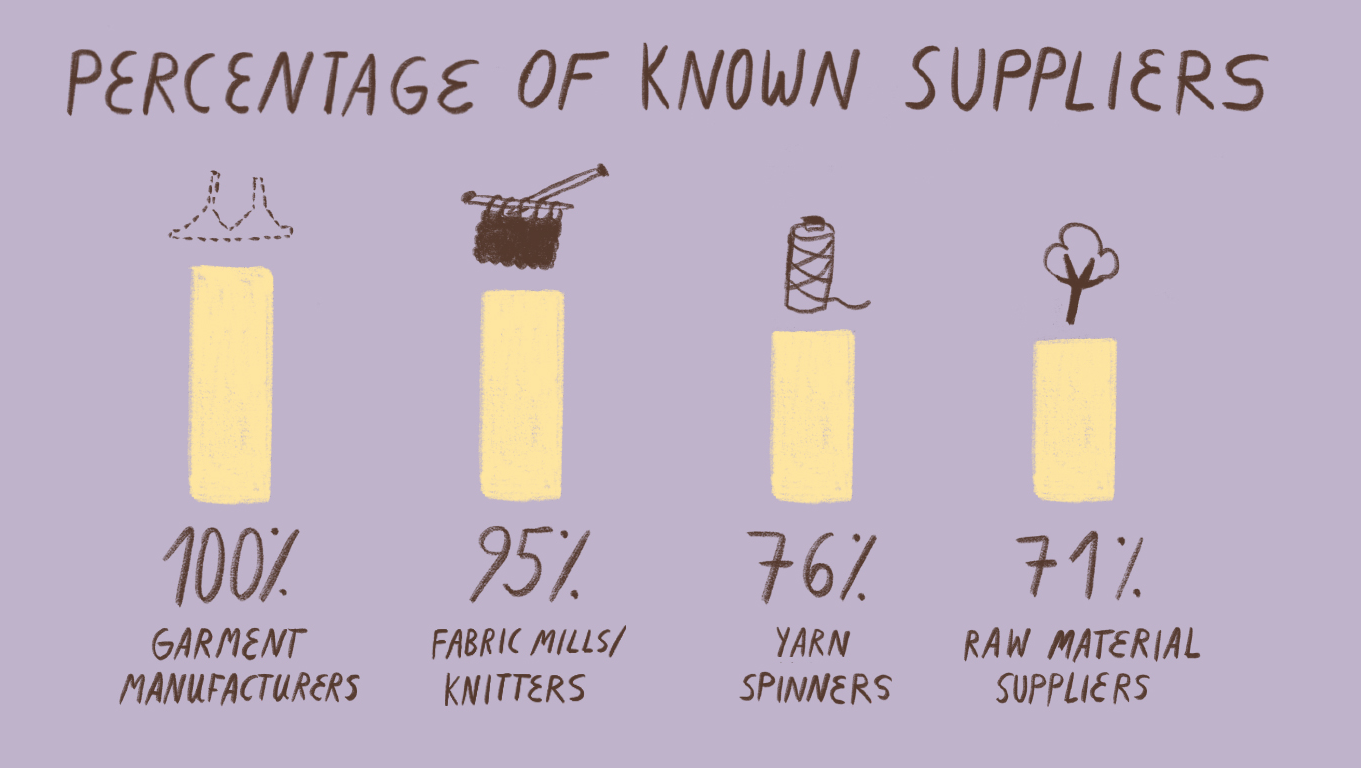

It’s very important for us to know how and where our products are made. Plus, it helps us to know our full climate impact.

Here’s where our products are made:

Our Low Impact Store

A big change in our supply chain has been the opening of our first-ever store in Copenhagen in November 2021. We worked to create a physical space that breathes life into our values and approach to sustainability, while providing a space to support and foster our community.

Our first physical store is a low impact shopping experience.

Visit it at Pilestræde 35, Copenhagen, Denmark.

Designing with dogmas

When planning our first store, we actively sought to think sustainability into every aspect of the store design. We did so by setting up the following set of rules to be complied with: